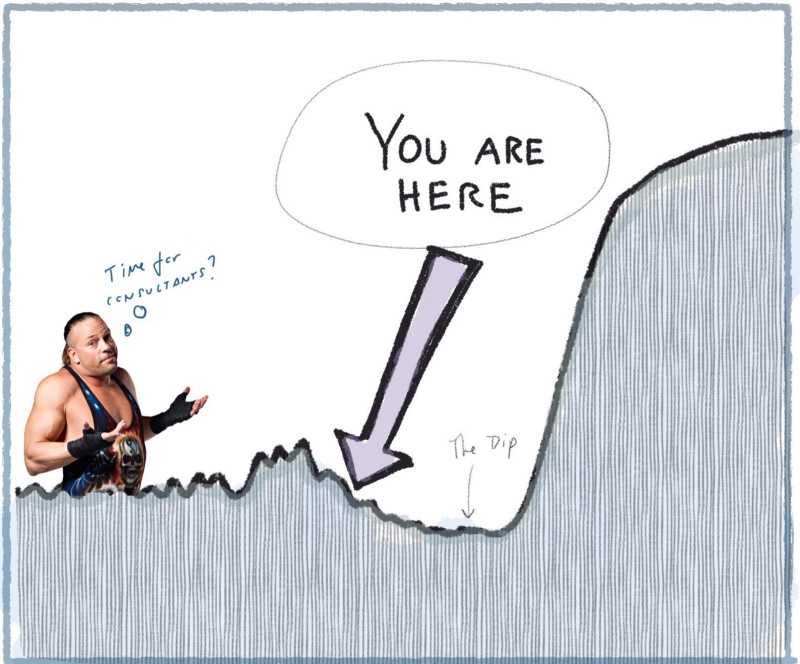

Sharing an email to a friend attempting to change her company as an internal change agent. The title of this post (and the drawing) is not wishful thinking. In less optimized systems, there’s always some low hanging fruit. For some reference, my friend has some access to the CEO (see point #1)

Sharing an email to a friend attempting to change her company as an internal change agent. The title of this post (and the drawing) is not wishful thinking. In less optimized systems, there’s always some low hanging fruit. For some reference, my friend has some access to the CEO (see point #1)

.

Subject: Instant Results! Guaranteed!*

[Friend]

Here’s how your company can jumpstart its continuous improvement efforts.

None of this is rocket science. None of this is “new”. It isn’t easy, but it also doesn’t require a special degree, a decade of training, or a certification. People will look at you like you’re proposing something C-R-A-Z-Y, but be confident this is time-tested (in knowledge work, not just manufacturing). The impediments are mostly imagined and self-imposed. You’ll hit counterintuitive stuff, but even that is reasonably well documented (I can send you some links).

Overarching Hint:

- Don’t rush into buying digital tools. Not required.

- Have faith. Have confidence that mistakes will be learning opportunities…hence the need for visualizing the system.

- (To points #3 and #5 below) you can always add value by making the current reality more clear.Caveat: This can work. But if your company is super toxic, managers are dead-set on “owning” change, and psychological safety is low, you might want to consider switching jobs. The guarentee is null and void:)

Steps:

- Get the CEOs buy-in. The mandate (and support) for the stuff below needs to come from her. Have the CEO set the context for the initiative, and make sure that she stresses the need for psychological safety (share some articles on psych safety to highlight how important it is). Make sure she invites people to participate (vs. imposing). Reiterate that this IS business-as-usual, not something tacked on to the real work. Finally, make public some sort of tangible goal like:

Sustainable shortest lead time, best quality and value (to people and society), most customer delight, high morale, safetyNote the counterbalancing statements here. It’s not FAST without VALUE and QUALITY, for example, and it is not unsustainable speed. Repeat this mission over and over.

Find a wall. Buy some tape, index cards, magnets, markers, stickies, string, and various stickers. Total cost $100 (on the high end) until you destroy the paintjob. Solution…you maybe need to cover the wall with something ($1000). Buy one or two books on Kanban for 20 odd interested and motivated volunteers representing a cross-section of your business (~$50x20 = $1,000). If you need a inspirational nudge, consider brining in a Kanban coach for the day ($2,000 — $5,000).

Visualize the work. All of it. Down to the story level (you can use checkboxes for tasks if you like). Repurpose your ticketing tool (e.g. Jira) as a “dumb” ticket repository for collaboration, notes, the integrations, etc. Make working agreements explicit, and put those up on the board — typically below the board — as well. Remember to visualize. ALL of the work: the meetings, reviews, syncs, SLAs, etc.

Get as “broad” as you can (without totally pissing people off). Hybrid boards — that go from company goals, through business initiatives, down to stories — are entirely possible. With some creativity, a single 10 foot x 17 foot board can suffice for 600 engineers and 60–80 teams. That said, this will work with any relatively contained system, provided the interfaces out if / into the system are clear.

Give your employees the following mission (and reassurance): “your mission is to make sure reality — regardless of how uncomfortable that reality is — is reflected on this board! No one will be punished for calling things as they are.” Keep tweaking the board to reflect reality. Embrace the zen of seeing things as they are. This is vitally important. It has to, on some level, become “fun” (even when it is painful).

Convene at the board. Get eyes on it. Run daily meetings by it. Always reiterate #5 above. A physical board will seem “SO INEFFICIENT”, but it is this inefficiency that triggers a disruption of automatic thinking. Stick with it. You’ll see it in people’s eyes when it “clicks”. “Wait a second…we’re doing way too much at once!”

Let’s say that the team is currently not using work-in-progress (WIP) limits. That’s fine. Don’t use them. Or that they’re running the system as a push system (not a pull system)…then don’t enforce a pull system. Just commit to visualizing reality. Or that there are super secret “fast lanes”…visualize those. Or secret back door meetings: indicate those with a black paper box (literally). You’ll tweak these things with time, so be patient. Don’t impose WIP limits, rather invite teams to use them as a tool at a later point (see #8 below).

Very quickly, the board will send you a signal of sorts. It will be blatantly obvious where a problem/opportinity is lurking. Use POPCORN to run experiments to address the issue. Note that POPCORN is itself a Kanban system. Limit your change in progress, and make your experiments “safe to fail”. Realize that you’ll need to stress the system slightly, but that too much stress can (probably will) cause collapse.

Your key tools for continuous improvement (and to elicit more information) are to use WIP limits, add buffers/queues, establish classes of work, observe cycle time and lead time, further clarify working agreements, and introduce events like more broad retrospectives. The books will define these things. Reiterate to the team that very few things (e.g. centralization, specialization, etc.) are wrong, but that we tend to be biased in a certain direction and need to challenge those biases. Present the idea of local vs. global optimization and stress that local optimization can be good to test ideas, but that there’s always a tension between the two. Finally, explain that continuous improvement takes time. It is OK to pragmatically adjust in the short term as you work to resolve an impediment (e.g. do something less than optimal).

Another tool is something like Cost of Delay which describes value as it relates to time. This can be a vitally important lens for making sound economic decisions. On some level this (or something like it) is the missing link as it ties improvements to business value, not just proxies like cycle time and lead time. Very Important! You don’t want to ship crap stuff faster and call it a win.

Work hard to share the idea that our intuitions tend to serve us well in most areas of our life, but that many things about product development are counterintuitive (mostly due to the non-tangible nature of the work and the inherent complexity in what we do). The team needs to develop an openness to trying things that don’t “make sense” initially, and to gauge the impact using data. One of the biggest intuition traps is the tendency to optimize for resource efficiency (busyness) over throughput (rate of value moving through system).

Rinse and repeat. Stick with it. Practice. Cultivate a core group of “system designers” who are more savvy about the dynamics of the system, and can coach others to “see” and navigate the intuition traps. After an initial period of rapid iteration, you can swap in a digital board if like.

In most unoptimized systems — systems that haven’t enjoy work in progress limits, and have not been operated as pull systems — you will see rapid improvement. The basics = big wins. That high rate of improvement can’t be sustained indefinitely, but some improvement is always possible (to defeat entropy if anything).

Above all, consider your own health and needs. If the org can’t figure this out, find a place that will. You’ll feel more empowered.

Cheers

John

*Maybe not at this job, but eventually…